In a world where technology plays an integral role in our daily lives, the constant wear and tear on electronic devices can be frustrating. From cracked screens to malfunctioning circuits, these issues not only inconvenience us but also contribute to the growing problem of electronic waste. However, there is hope on the horizon as a groundbreaking innovation emerges from Silicon Valley – self-healing electronics.

Imagine a future where your smartphone repairs itself after being dropped or your laptop automatically fixes its own internal components when they become damaged. This seemingly futuristic concept is now becoming a reality thanks to pioneering efforts by a Silicon Valley startup that aims to revolutionize the way we interact with technology.

But what exactly are self-healing electronics and how do they work? In this article, we will delve into the fascinating world of self-healing materials, examine their key applications, explore the innovative startup behind this groundbreaking technology, discuss its potential impact on product lifespan and reducing electronic waste, as well as analyze its challenges and limitations. We will glimpse into the future prospects and applications of this game-changing innovation.

Join us on this exciting journey as we uncover how self-healing electronics are poised to transform our technological landscape forever!

Background of Self-Healing Materials

Self-healing materials have been an area of intense research and development in the field of materials science over the past few decades. The concept behind self-healing materials originated from nature itself, where living organisms possess the ability to repair and regenerate damaged tissues or structures.

Inspired by this innate healing capability found in biological systems, scientists began exploring ways to replicate these remarkable properties in synthetic materials. The goal was to create a new class of materials that could autonomously repair damage caused by external factors such as impact, wear, or even harsh environmental conditions.

One breakthrough came with the discovery and understanding of self-healing polymers. These polymers contain special molecular arrangements that allow them to undergo reversible chemical reactions when subjected to mechanical stress. This unique property enables them to heal themselves on a microscopic level, sealing cracks or breaks and restoring their structural integrity.

Another significant advancement came through the integration of microcapsules within material matrices. These capsules are filled with healing agents that can be released upon damage, effectively filling gaps or voids and restoring functionality.

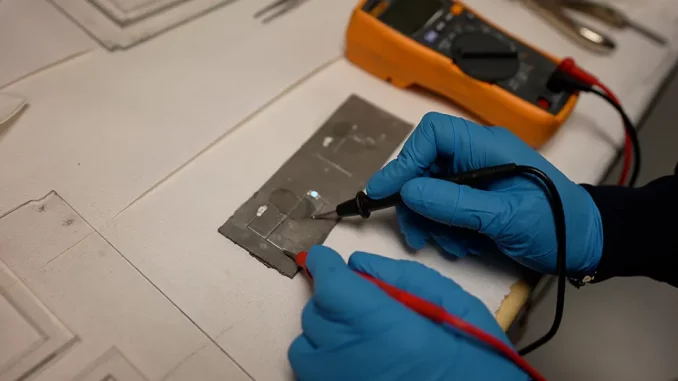

The evolution of self-healing materials has not only led to advancements in various industries but also opened up new possibilities for cutting-edge technologies like self-healing electronics. By incorporating these innovative materials into electronic devices, researchers aim to overcome common issues such as circuit failures due to wear-and-tear or physical damage caused by accidents.

As we delve deeper into the realm of self-healing electronics, it becomes evident that this technology holds immense potential for revolutionizing how we perceive and interact with our everyday gadgets. Stay tuned as we explore further into this exciting domain!

Overview of Self-Healing Materials

Self-healing materials have emerged as an innovative solution to address the limitations of conventional materials. These futuristic substances possess the ability to repair themselves when damaged, leading to extended durability and reliability.

One key characteristic of self-healing materials is their intrinsic capability to detect and respond to damage autonomously. They can sense cracks or fractures in their structure and initiate a healing process without any external intervention. This unique property sets them apart from traditional materials, which require manual repairs or replacement.

The underlying mechanism behind self-healing involves the use of microcapsules or vascular networks within the material’s matrix. These encapsulated healing agents are released upon rupture or damage, filling in the gaps and restoring integrity to the structure. Some self-healing materials even leverage chemical reactions that occur on a molecular level, allowing for seamless regeneration.

The applications of self-healing materials are vast and diverse across various industries including aerospace, automotive, electronics, construction, and healthcare. In aerospace engineering, these materials can enhance aircraft structural components’ resistance against fatigue cracks caused by cyclic loading. Similarly, in electronics manufacturing, they can prevent circuitry failures due to wear-and-tear or mechanical stress.

In addition to extending product lifespan and improving reliability in critical applications like infrastructure development and medical devices, self-healing materials also contribute significantly towards reducing environmental impact by minimizing waste generated through regular maintenance cycles.