Introduction

Brief overview of the role of robotics in manufacturing.

Importance of efficiency and precision.

History of Robotics in Manufacturing

The evolution from manual to automated processes.

Early adoption of robotics in manufacturing.

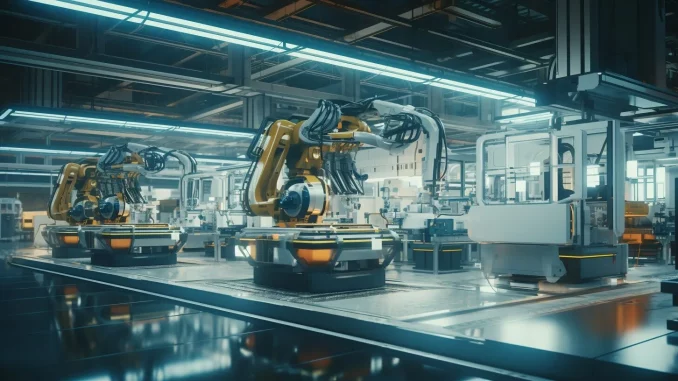

Current State of Robotic Technology

Advancements in robotic technology.

Types of robots used in manufacturing.

Enhanced Efficiency

How robotics improves production speed.

Case studies of efficiency improvements.

Unmatched Precision

Precision capabilities of modern robots.

Impact on product quality.

Cost-Effectiveness and ROI

Cost analysis of implementing robotics.

Return on investment examples.

Integration with IoT and AI

The synergy between robotics, IoT, and AI.

Examples of integrated systems.

Workforce Implications

The changing landscape of manufacturing jobs.

Upskilling and new job opportunities.

Customization and Flexibility

Robotics in small batch production.

Customization capabilities.

Safety Enhancements

How robotics improve workplace safety.

Reduction in work-related injuries.

Environmental Impact

Eco-friendly aspects of robotics in manufacturing.

Sustainability and waste reduction.

Global Trends in Robotic Manufacturing

Adoption rates across different countries.

Emerging markets for robotic manufacturing.

Challenges and Limitations

Technical and logistical challenges.

Addressing the limitations.

Future Outlook

Predictions for future advancements.

The role of innovation in robotics.

Conclusion

Summarizing the impact of robotics in manufacturing.

Final thoughts on the future of manufacturing.